Product Description

Zhengde hot rolled carbon steel coil can be cuatomized in size.The width specifications of hot-rolled steel coils are generally 1000mm-2500mm, of which the width below 1000mm is called narrow plate, and the width above 2500mm is called wide plate. Common width specifications are 1000mm, 1219mm, 1250mm, 1500mm, 1800mm, 2000mm, 2200mm, 2500mm, etc. The weight of hot rolled carbon steel coil also can be customized according to customer's requirement.

|

Cold Rolled/ Hot Rolled Ms Carbon Steel Coils

|

|

Thickness

|

Hot Rolled Thickness:2.75mm-100mm, as Your Request Cold Rolled Thickness:0.2mm-3mm, as Your Request

|

|

Width

|

1250-2500mm,or as Your Request ( regular width 1000mm, 1250mm, 1500mm )

|

|

Coil ID

|

508mm or 610mm

|

|

Coil Weight

|

3 - 8 ton or as Your Request

|

|

Standard

|

ASTM EN DIN GB ISO JIS BA ANSI

|

|

Steel Grade

|

Q195, Q215,Q235,Q345,ST37, A36,1017 1020 1025 1030,A106,SS400, 45# ,16Mn, SPHC,SGCC,CGCC

|

|

Technique

|

Hot rolled cold rolled as Your Request

|

|

Surface Treatment

|

Bare,Black,Oiled,Shot Blasted,Spray Paint,Coated,Galvanized,or as Your Request

|

|

Application

|

Applies to appliances construction, machinery manufacturing, container manufacturing, shipbuilding, bridges, etc.

|

|

Package

|

Standard Export packing(Plastic film in the first layer,second layer is Kraft paper. Third layer is galvanized sheet)

|

Our Advantages

High Strength

Hot-rolled steel coil product introduction: Hot-rolled steel coil and strip products are made of slab (mainly continuous casting slab) as raw material, and are made into strip steel by rough rolling unit and finishing rolling unit after heating. The hot steel strip coming out of the last rolling mill of finishing rolling is cooled to the set temperature by laminar flow, rolled into steel strip coil by coiler, and the cooled steel strip coil.

Adequate inventory

Spot inventory of steel coils with various material properties: ordinary carbon structural steel coils, low alloy steel coils, alloy steel coils, wear-resistant steel coils, steel coils for cold forming, structural steel coils, automotive structural steel coils, steel coils for corrosion-resistant structures, mechanical structures Steel coils, steel coils for welded gas cylinders and pressure vessels, steel coils for pipelines, etc.

Attention to detail

The surface quality is good. Compared with ordinary hot-rolled coils, Zhengde hot-rolled coils have removed the surface oxide scale, improved the surface quality of steel, and are convenient for welding, oiling and painting.

The dimensional accuracy is high, and after leveling, the coils shape can be changed to a certain extent, thereby reducing the deviation of unevenness. Improved surface finish for enhanced appearance

Provide deep processing

Relying on Zhengde's sufficient steel coils resources, it reduces the pressure on customers' inventory. It can be cut according to drawings, or directly cut into graphics required by customers, such as circles, rectangles, flanges, bearing housings, rolling mill racks, and rolling mill arches, etc. The cutting precision is high. , the incision is smooth and tidy, and the machining allowance is small.

Quality first: production and inspection in strict accordance with production standards;

Quality first: production and inspection in strict accordance with production standards;

Price advantage: discounts based on real market prices;

Transaction security: There will be no loss of customer funds;

After-sales guarantee: the customer's problem is our problem;

Long-term cooperation: quality assurance, price advantage, sincere service can last for a long time.

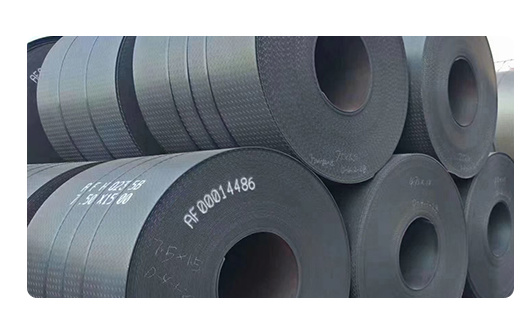

Detailed Photos

Packaging & Shipping

Company Profile

Shandong Zhengde Metal Manufacturing Co., Ltd. is a production and sales company integrating hot-rolled steel coils, cold-rolled steel coils, galvanized steel coils, color-coated steel coils, section steel, steel pipes, steel wires, metal mesh, stainless steel, aluminum, copper and other metal products integrated large enterprises. Five production and sales bases have been formed in Binzhou, Liaocheng, Wuxi, Tianjin, Jinan and Tai'an, with more than 100 production lines, 4 nationally recognized laboratories, 2 technical engineering centers, and 5 enterprise technology centers. Products are exported to more than 50 countries and regions such as North America, South America, Europe, Africa, Oceania, Middle East, and Southeast Asia.

Shandong Zhengde Metal Manufacturing Co., Ltd. is a production and sales company integrating hot-rolled steel coils, cold-rolled steel coils, galvanized steel coils, color-coated steel coils, section steel, steel pipes, steel wires, metal mesh, stainless steel, aluminum, copper and other metal products integrated large enterprises. Five production and sales bases have been formed in Binzhou, Liaocheng, Wuxi, Tianjin, Jinan and Tai'an, with more than 100 production lines, 4 nationally recognized laboratories, 2 technical engineering centers, and 5 enterprise technology centers. Products are exported to more than 50 countries and regions such as North America, South America, Europe, Africa, Oceania, Middle East, and Southeast Asia.

Certifications

Shandong Zhengde Metal Manufacturing Co., Ltd. is a production and sales company integrating hot-rolled steel coils, cold-rolled steel coils, galvanized steel coils, color-coated steel coils, section steel, steel pipes, steel wires, metal mesh, stainless steel, aluminum, copper and other metal products integrated large enterprises. Five production and sales bases have been formed in Binzhou, Liaocheng, Wuxi, Tianjin, Jinan and Tai'an, with more than 100 production lines, 4 nationally recognized laboratories, 2 technical engineering centers, and 5 enterprise technology centers. Products are exported to more than 50 countries and regions such as North America, South America, Europe, Africa, Oceania, Middle East, and Southeast Asia.

Shandong Zhengde Metal Manufacturing Co., Ltd. is a production and sales company integrating hot-rolled steel coils, cold-rolled steel coils, galvanized steel coils, color-coated steel coils, section steel, steel pipes, steel wires, metal mesh, stainless steel, aluminum, copper and other metal products integrated large enterprises. Five production and sales bases have been formed in Binzhou, Liaocheng, Wuxi, Tianjin, Jinan and Tai'an, with more than 100 production lines, 4 nationally recognized laboratories, 2 technical engineering centers, and 5 enterprise technology centers. Products are exported to more than 50 countries and regions such as North America, South America, Europe, Africa, Oceania, Middle East, and Southeast Asia.